Since its inception in 2012, CealTech has sought to be an industry leader of high quality graphene at industrial scale,, thereby to unlock graphene full potential. Towards this end, CealTech has entered a global, strategic collaboration agreement with Caltech (California Institute of Technology) focused on the research and development of graphene and utilizing Caltech’s patented graphene production technique (issued US patent 9,150,418). The Collaboration and License Agreement was made effective as of the 15th day of June, 2016 and grants CealTech exclusive rights for use of the patented technique into its own graphene production unit, FORZATM (patent pending), which has the potential to produce graphene at large scale and competitive price, with effective yields and a purity sufficient so as not to impair graphene’s desired chemical properties.

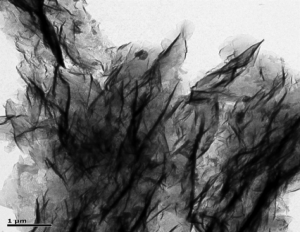

The backbone of CealTech’s graphene production method is the Plasma Enhanced Chemical Vapor Deposition (PE-CVD) technique. The purity, electronic properties, and mechanical strength of the PE-CVD graphene is comparable to those of pristine graphene. In addition, CealTech’s unique method enables short production time, reduced process temperatures, single-step processing (e.g. continuous production), superior control over the number of produced layers, and the ability to directly functionalize the graphene per the intended application without any chemical modification. The TEM (Transmission Electron Microscope) image in the figure below highlights the unique structure of CealTech’s 3D graphene, which offers better bonding with the surrounding matrix, hence improving the interfacial load transfer.

TEM image of CealTech’s 3D graphene.

First trials

As a startup trial, CealTech have started to grow 16 different types of graphene (pure as well as functionalized), by alternating the process settings. Although we acknowledge that further optimization is still required, it is reasonable to say that the results obtained thus far are beyond encouraging, where our unique production method can enable direct tailoring of the graphene (i.e. group-functionalization) to suit the specificities of the intended applications, and this without requiring any chemicals.